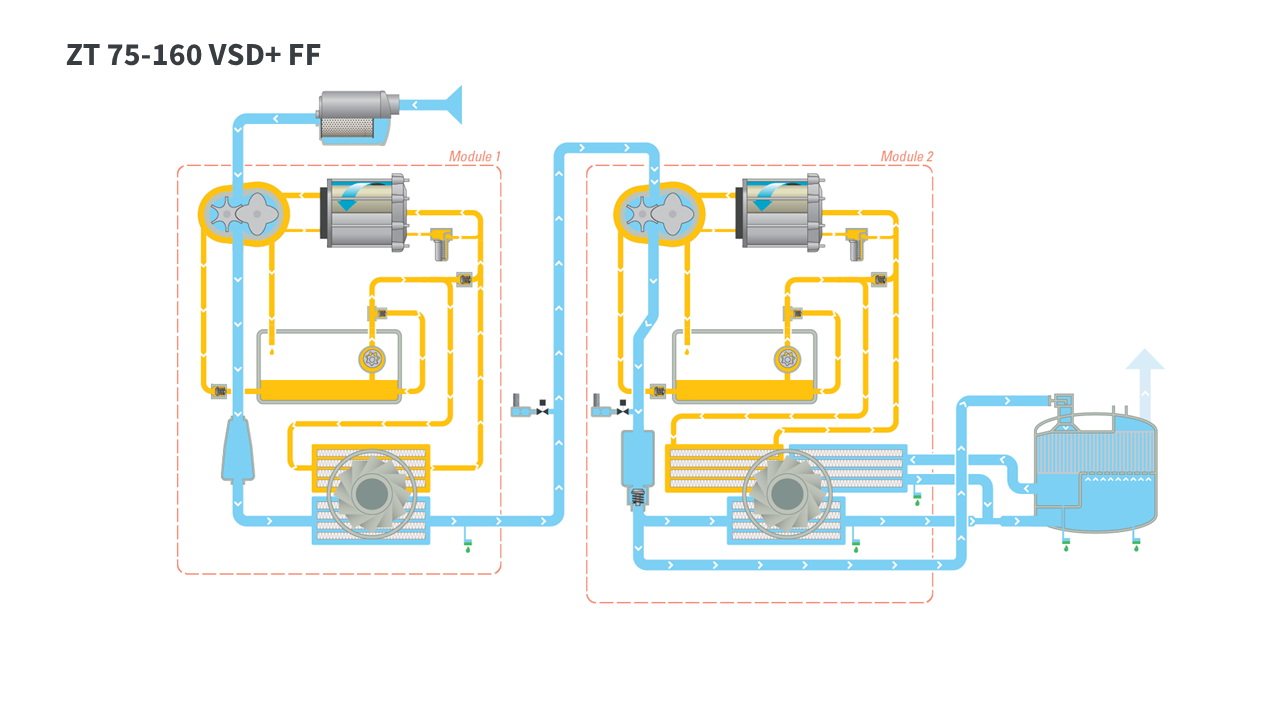

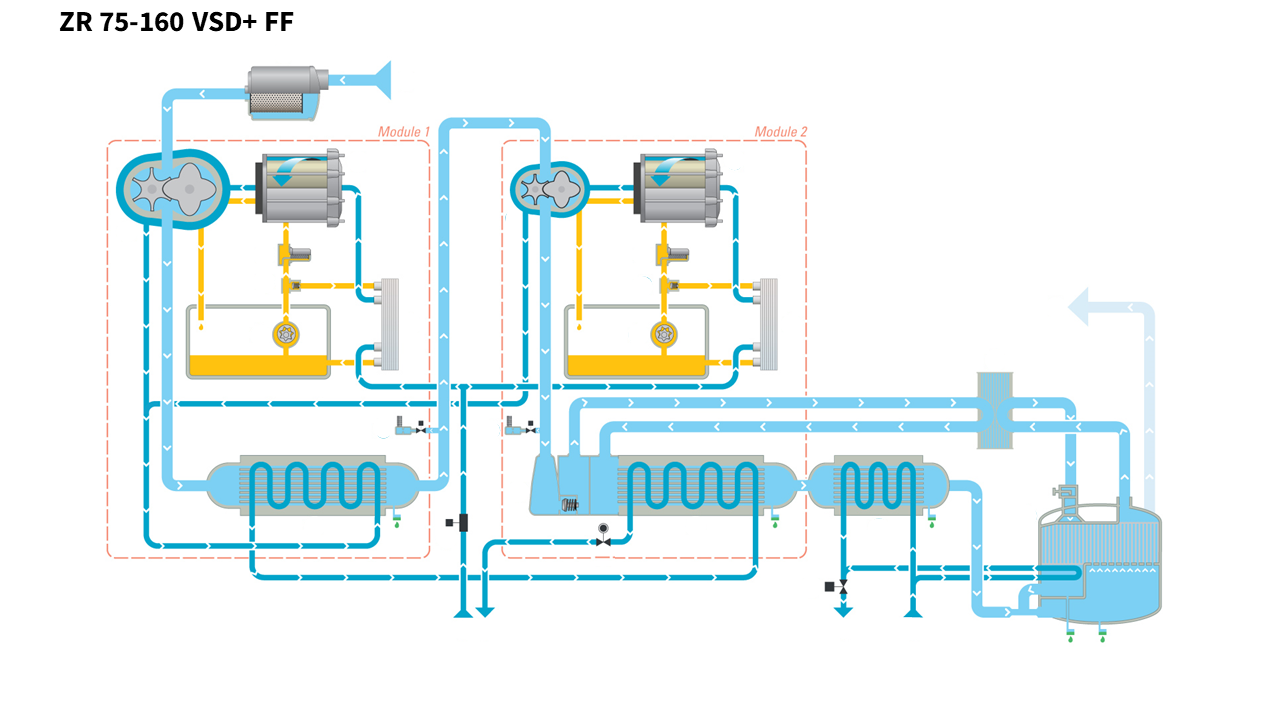

Process flow, oil flow and cooling flow – step by step.

Flowchart

Filtration & compression

The air is drawn into the compressor through the inlet filter where the air is cleaned. It then continues to the first compression stage where the air is compressed to an intermediate pressure.

Cooling & second compression

After the first compression, the air is cooled down in the intercooler. Once the air is cooled down, it passes through a moisture separation system before entering the highpressure stage. In the high-pressure stage, the pressure is brought to its final pressure.

Exchanging heat & cooling

The hot wet compressed air at the outlet of the highpressure stage goes through the pulsation damper with integrated check valve to the heat exchanger. Here it

transfers the heat to the integrated dryer used further in the process.

The air continues to the aftercooler where it’s cooled

down and the moisture get’s separated and drained.

Integrated dryer

The cooled wet compressed air is now mixed with 40% of the cooled regeneration air and enters the dryer. The dry compressed air with guaranteed dew point is now ready for use in your application.

Heat exchanger

40% of the dry air goes into the heat exchanger, where it picks up the heat from the incoming hot wet compressed air. This dry and hot regeneration air enters the

regeneration section of the drum, which passes through the regeneration cooler where it is cooled down and moisture is separated and drained. Afterwards it is mixed with the incoming cooled wet compressed air.

Oil

The yellow lines represent the oil flow of the compressor. Oil is pumped from the reservoir through a high efficiency filter to provide clean, cooled oil to the gears for lubrication. Afterwards the oil flows back into the reservoir. There also is a bypass valve that allows the oil to flow to the oil cooler, so the optimal temperature is guaranteed, increasing efficiency and durability of our components.

Water

The dark blue lines represent the water flow. Cooling water is brought into the cycle and splits towards the both modules and the dryer.

First of all, the cooling water is directed to the integrated dryer to cool the air.

Secondly, the water is goes to both the inter- and aftercooler to reduce the temperature of the compressed air.

Lastly, the water splits to the oil coolers to reduce the temperature of the oil. It then passes through the jackets of the motor and elements to guarantee an optimal temperature. The water continues back to the cooler and

is directed further to the water outlet.