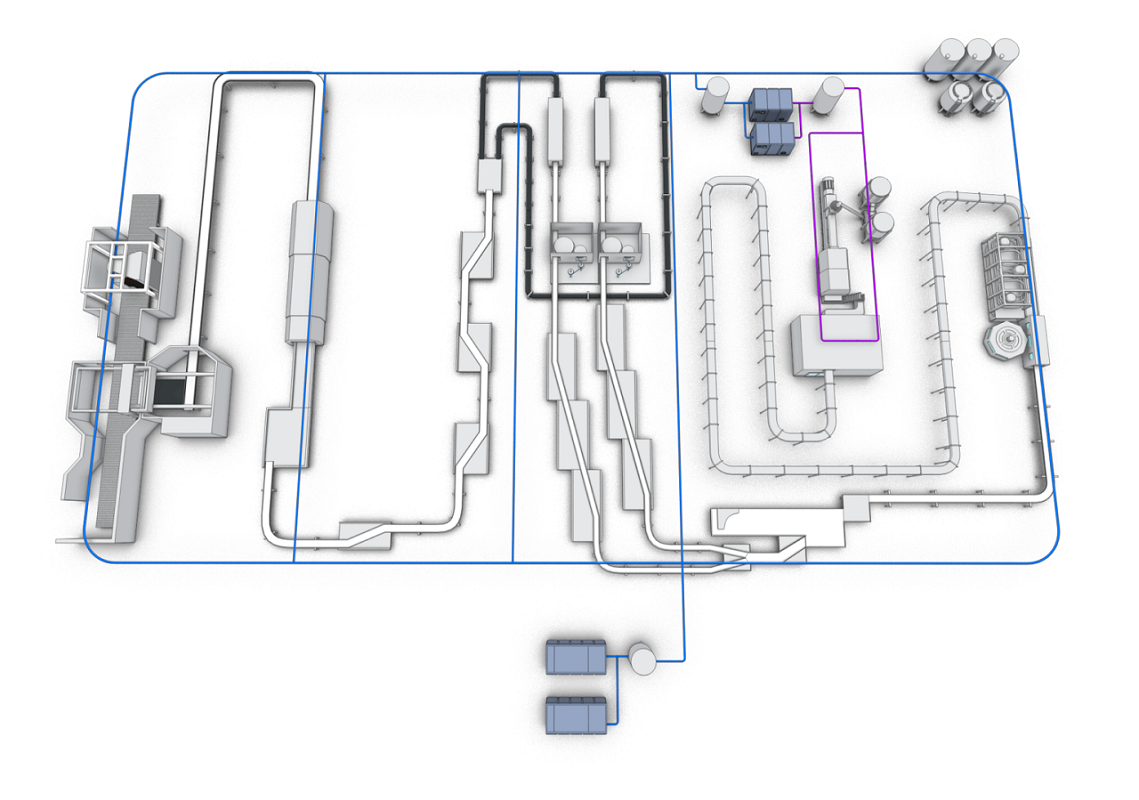

Optimum Compression technology

4 stage compression: best of thermodynamics

Four-stage compression with intercooling saves up to 10% energy when compressing air between 25 to 45 bar. It also lowers the operating cost (OPEX) significantly, despite the higher capital cost (CAPEX). Our ZD hybrid 4 stage solution is the best value for the PET industry.