Why using our Atlas Copco dryers?

Cost-effective dry air for your application

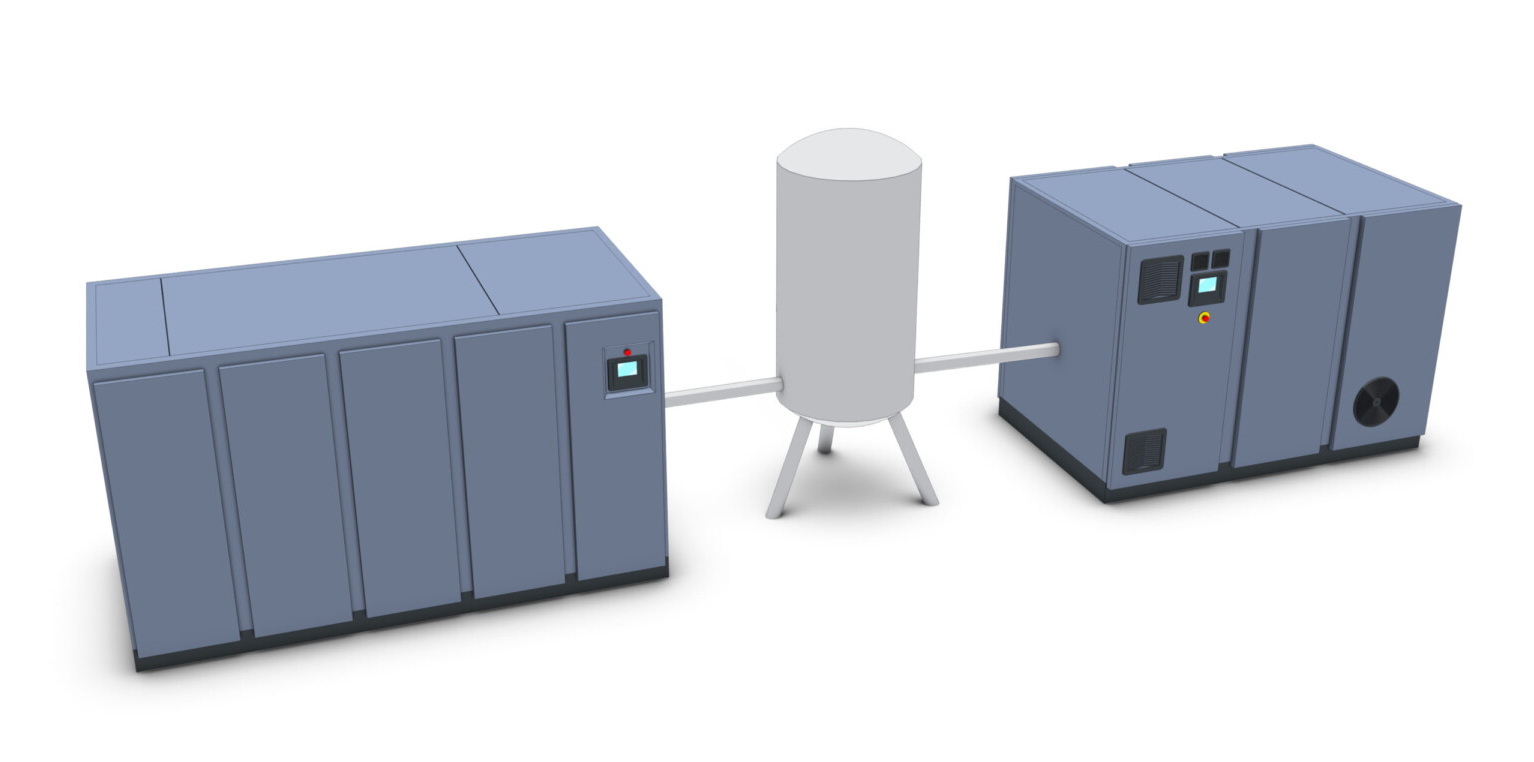

Our ZD optimized solution with the dryer in between the compressor and booster extend the service life of the booster and increase air quality at lower pressures. Conventional high pressure drying methods limit the scope of pressure reductions and energy savings. When using a high pressure refrigeration type air dryer, as the system pressure is lowered the pressure dew point rises increasing system contamination and production downtime. With the Atlas Copco ZD solution, air quality increases reducing maintenance costs while increasing production efficiency.