TDV AD 02

-

1

Axial fans

-

2

Atlas Copco Elektronikon® MkV S Touch

-

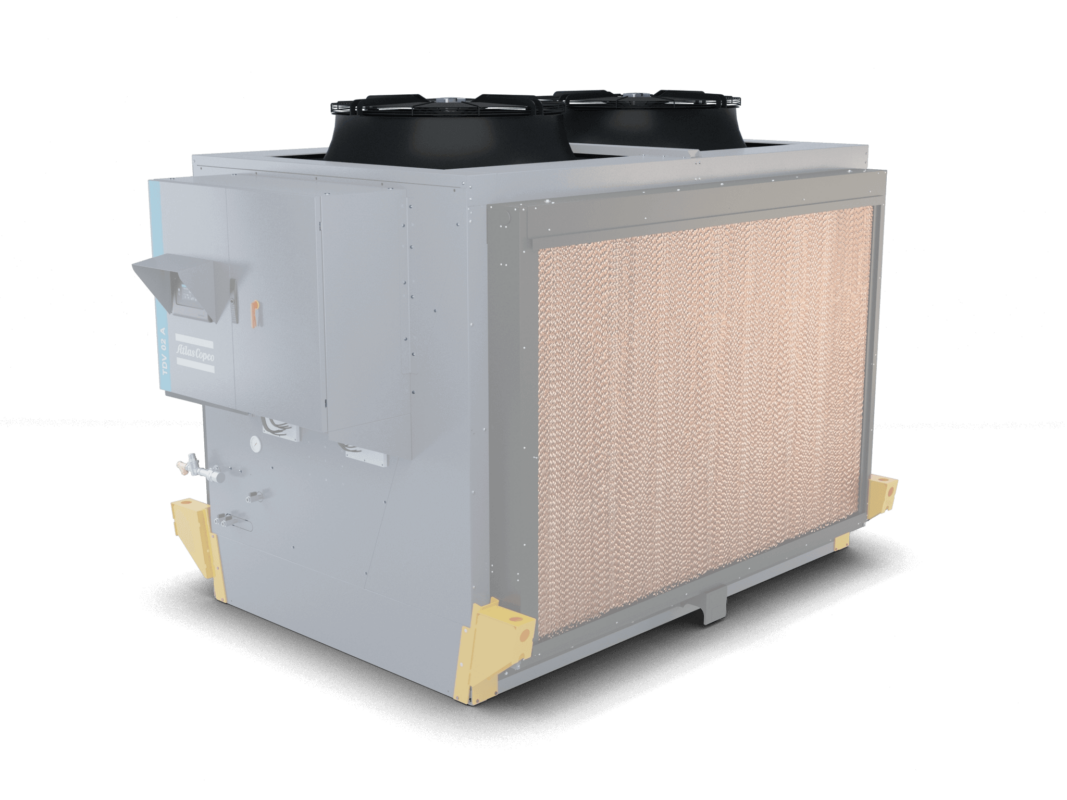

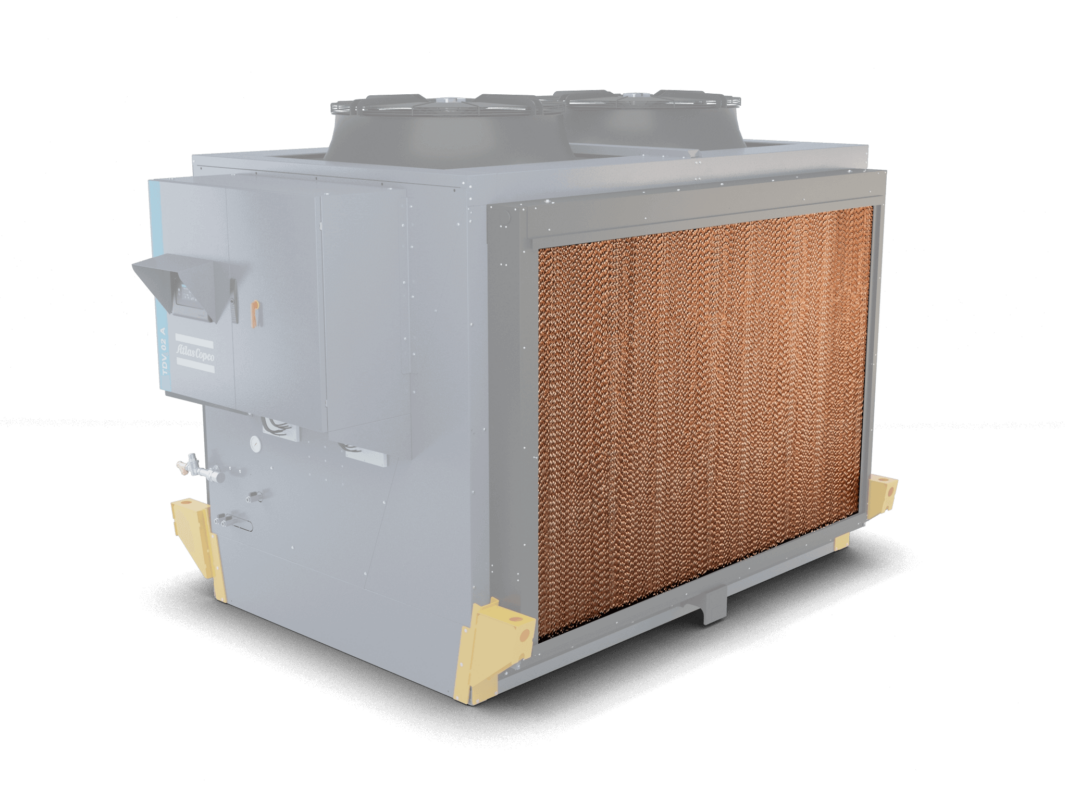

3

Adiabatic pads

-

4

Drainage system

-

5

Inlet/Outlet

-

6

Heat Exchangers

-

7

Drainage

-

8

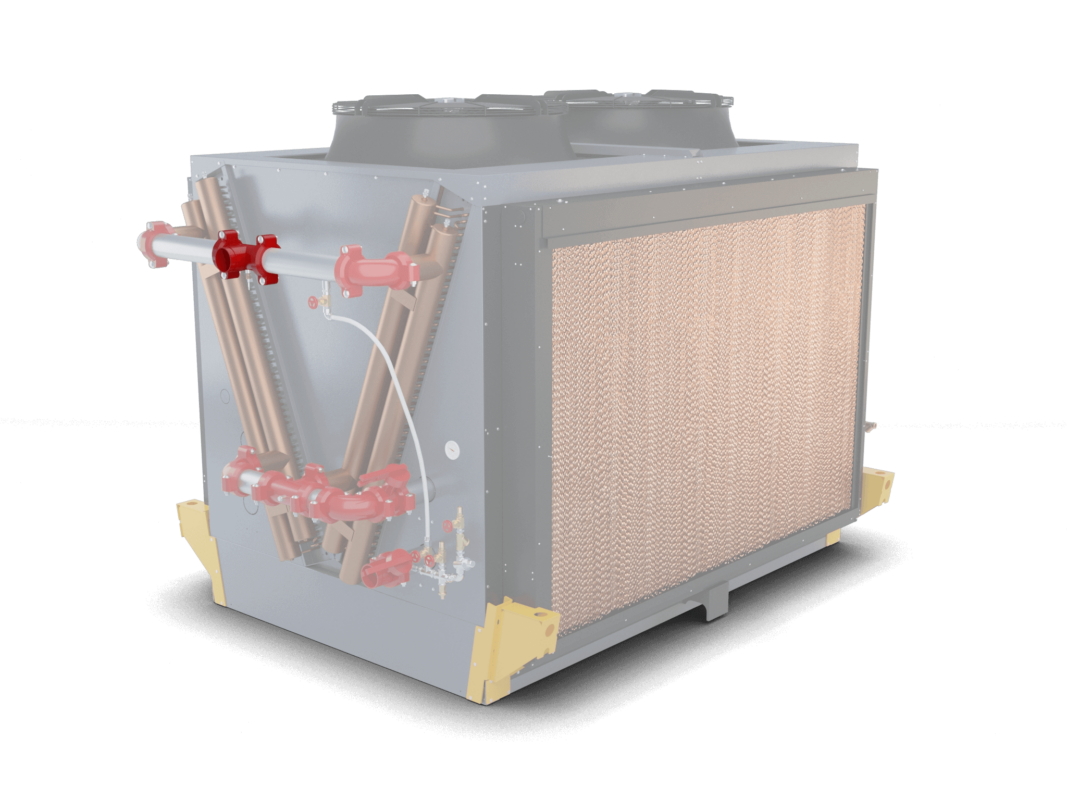

Irrigation System

-

9

Adiabatic solenoid valves

-

10

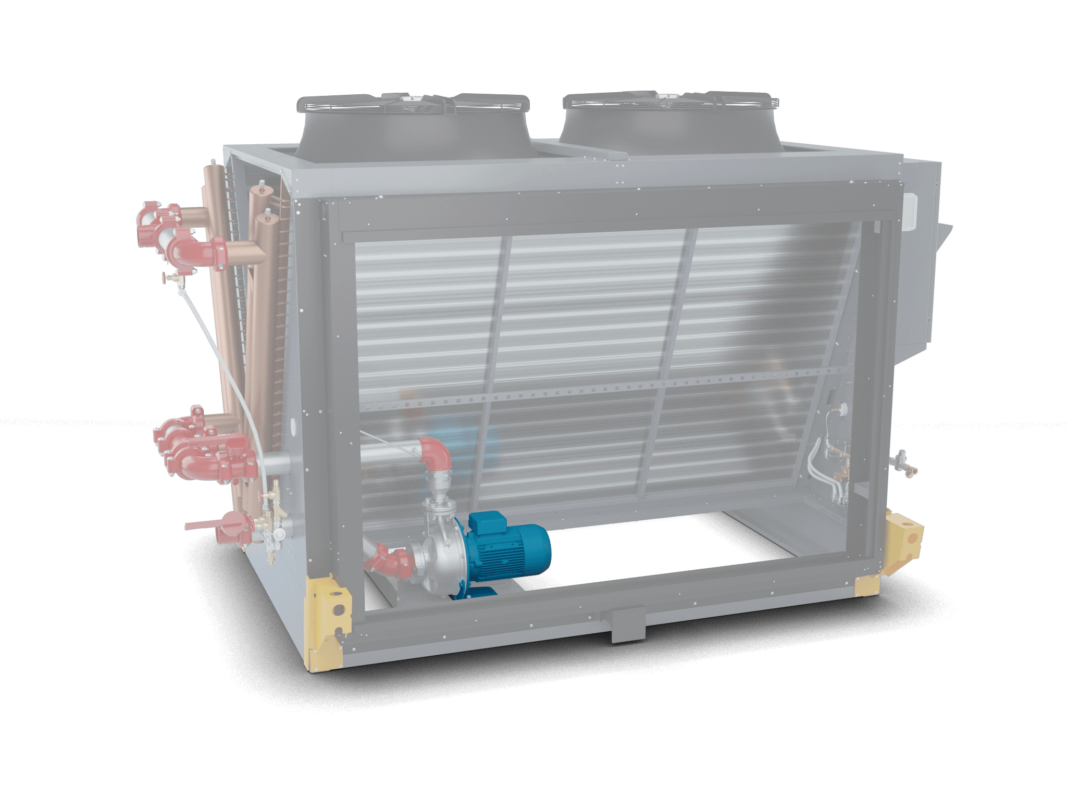

Pump

-

1

Axial fans

Possibility to reduce fan speed with controller enabling optimal temperature control for lower ambient temperatures.

-

2

Atlas Copco Elektronikon® MkV S Touch

Atlas Copco’s standard solution with a touch interface specifically designed for coolers, 4G connectivity for Smartlink™, and the option of a Modbus Gateway. This solution effectively integrates into existing systems, provides a user-friendly interface for easy startup, allows effective control of cooler parameters, enables remote monitoring via the Internet, and seamlessly integrates into factory control systems.

-

3

Adiabatic pads

These humidifying pads are made from corrugated cellulose sheets impregnated with additives and resins. They enhance humidification efficiency, have low pressure drops, high mechanical strength, and a long service life (5-7 years). Additionally, they are self-supporting, lightweight, and made from recyclable materials.

-

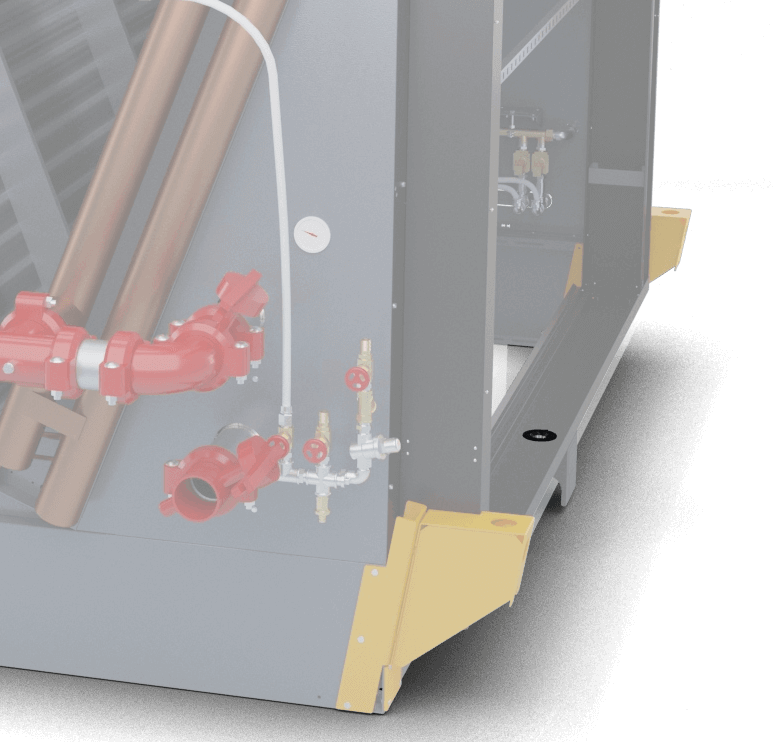

4

Drainage system

The adiabatic hydraulic system can be drained using discharge valves at the end of each season, and the base is equipped with drainage holes to allow rainwater to flow to the ground.

-

5

Inlet/Outlet

Simplified installation for the client with one inlet and one outlet.

-

6

Heat Exchangers

Finned pack heat exchangers provide high efficiency thanks to the extended heat exchange surface.

-

7

Drainage

Below the adiabatic pads, there is a drainage hole equipped with a patented capacity controller to regulate water consumption during adiabatic operation.

-

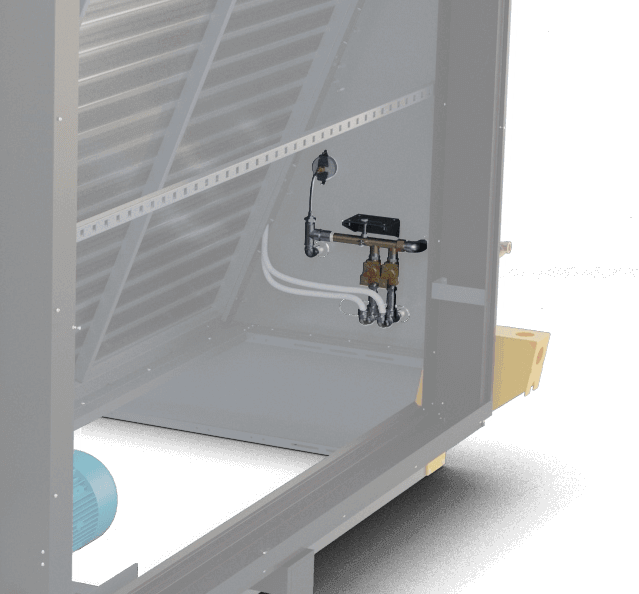

8

Irrigation System

The irrigation system features stainless steel pipes and aluminum bottom paneling.

-

9

Adiabatic solenoid valves

Each module is equipped with a solenoid valve controlled by MK5 providing the correct amount of water to the distribution pipes.

-

10

Pump

The centrifugal pump features 316L stainless steel housing and impellers, four pressure options (up to 6bar) across sizes A to D, an IE3 efficient motor for higher reliability, and meets installation requirements while achieving improved efficiency.