The compressors, blowers, dryers and other machines in a smart compressed air network have a real-time connection with the Atlas Copco central controllers, ensuring continuous data visualization and monitoring.

Smart insights into your installation

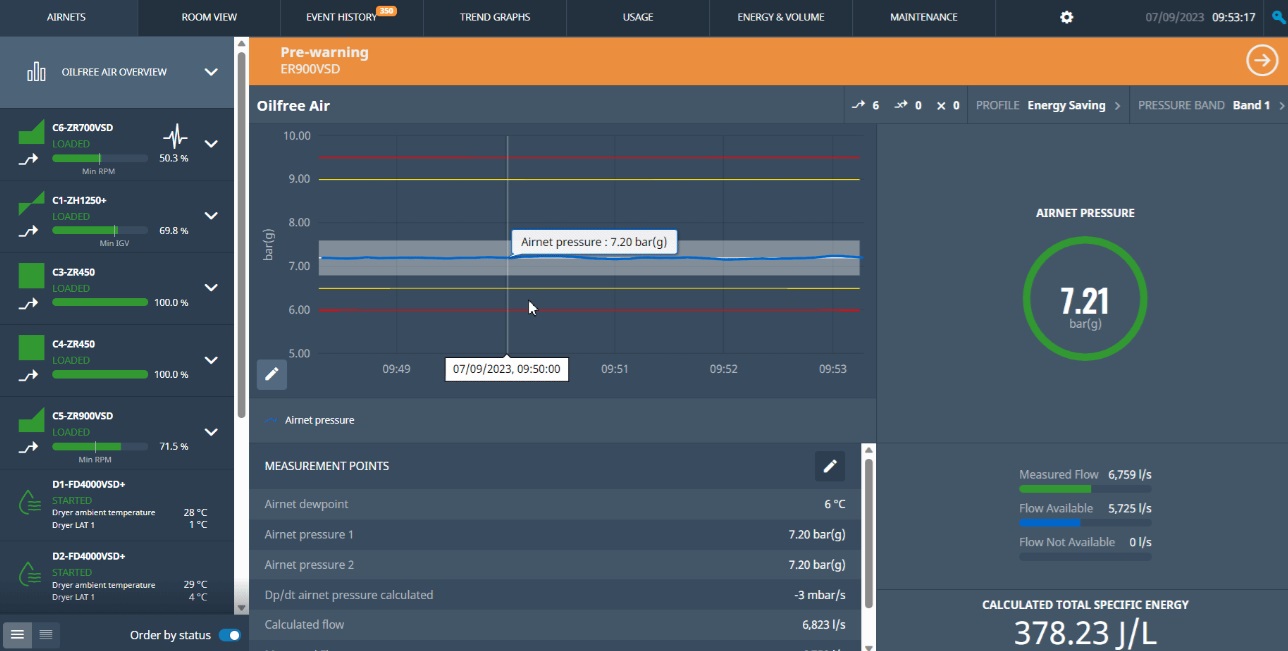

Airnets & event history

This section gives the overview of your installation. Via this screen you can find all the relevant data about your compressed air network or process.

You can immediately find the flow and pressure values for your airnets and connected machines.

Easily integrate or isolate machines from the Optimizer 4.0 or Equalizer 4.0 PRO.

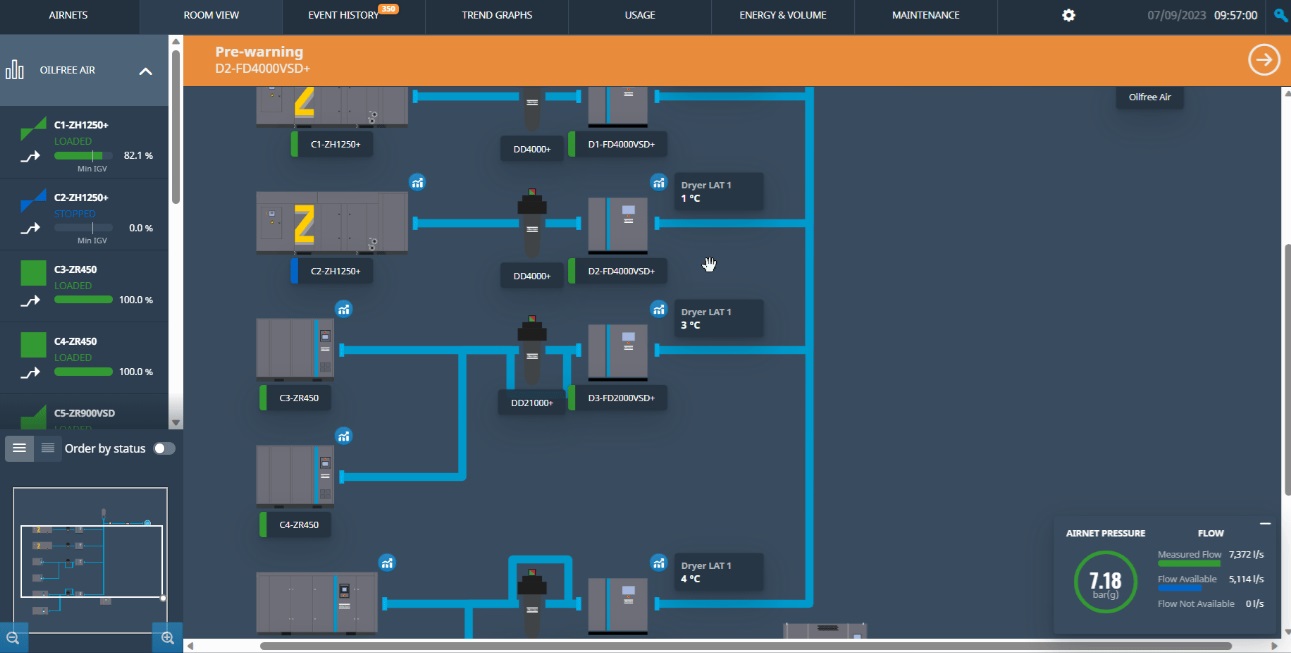

Room view

This SCADA view clearly shows you which machines are operating, what their operational parameters are and gives you insights into the consumption.

An intuitive and complete overview of your installation.

Flexibility to monitor different measurements and calculated values. You can even visualize the data from your own measurement devices.

Trend graphs & maintenance

Simply create custom trend graphs for the parameters which are important for your production plant.

Easily create graphs from machine and airnet datapoints. You can even connect your own measurement devices, such as flow meters, via the analogue input and trend those datapoints.

Export all the measured and calculated data for a detailed analysis.

As different components in the Compressed Air Network require specific maintenance, a clear and user-friendly maintenance management overview can be found on the central controllers.

Easily follow up on the required service, the overview is clearly indicating which is the next type of service and within how many running hours that is required.

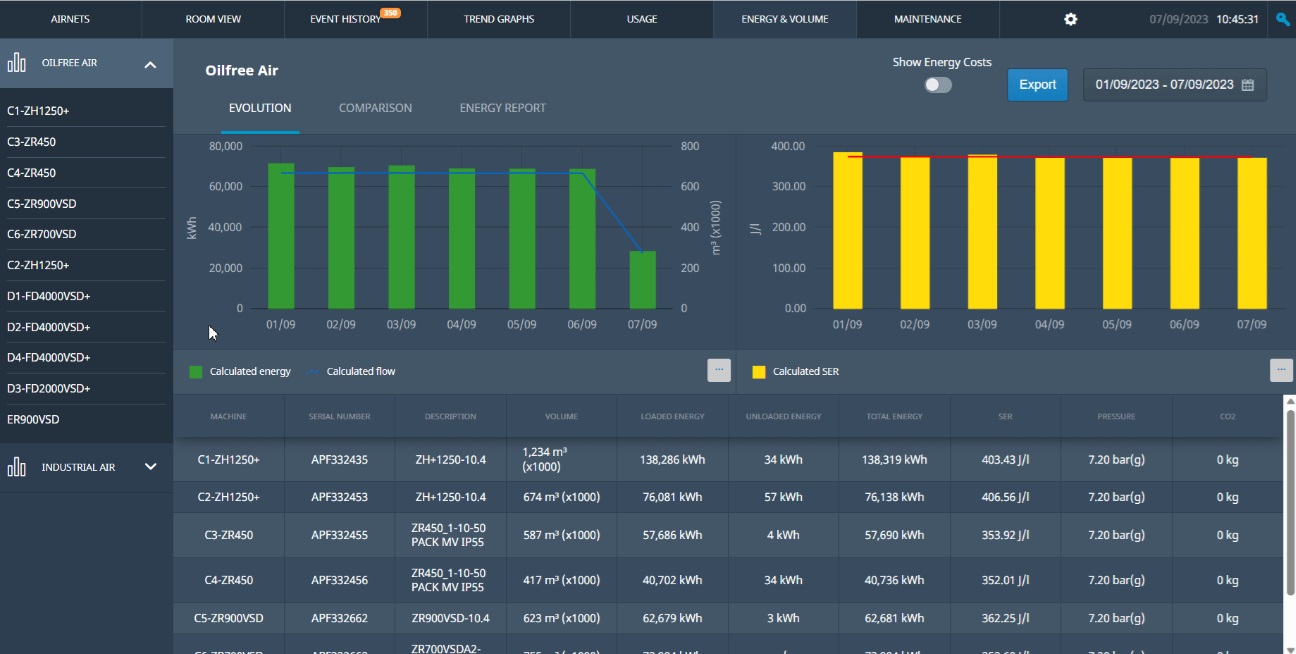

Energy & Usage insights

This view shows you all the energy and usage insights for machine parameters, compressed air & flow demand, power consumption and other notifications that can be viewed remotely via Local Area Network.

Clear insights on the power consumption, usage and CO2 of your installation.

Energy Report: Easily export a very detailed report for a specific period in your production calendar.

Data logging of minimum 30 days of measured and calculated data. Energy data is stored up to two years, compliant with ISO50001.