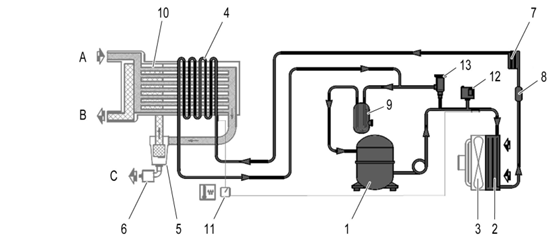

Working principle

1. Refrigerant compressor

2. Condensor

3. Motor fan

4. Air-to-refrigerant heat exchanger/evaporator

5. Water-air-separator

6. Condensate drain

7. Capillary tube

8. Filter

9. Liquid separator

10. Air-to-air heat exchanger

11. Dew point indicator

12. High pressure switch

13. Hot gas bypass valve

Air flow

Compressed air which needs to be dried enters the HE A-A section (10) and is then cooled by the outlet, in lower temperature & dried air. Due to the fact that the temperature decreases, the water vapor within the inlet air starts to condense. Then the air flows into the evaporator (4) and is cooled further down to the evaporating temperature of the refrigerant. More liquid water condenses. The cold air with liquid water droplet then flows through the WSD (5) where the liquid water is separated from the air. Liquid water is exhausted out via the drain valve (6). Next, the cold & dried air flows back to the HE A-A section (10) where it is warmed up by the inlet hot & wet air and then goes out through the air outlet of the heat exchanger.

Refrigerant flow

The refrigerant compressor (1) drives high temperature, high pressure refrigerant gas through the water-cooled/air-cooled condenser (2), where the refrigerant gas condenses into liquid refrigerant. Then the liquid refrigerant flows through the dryer filter (8) (to avoid moisture & particles), and then to the expansion element (expansion valve or capillary) (7). After passing through the expansion element (7), the refrigerant switches to much lower temperature & pressure. This refrigerant then enters the evaporator (4) and absorbs heat from the inlet hot compressed air to evaporate. After evaporating, gas (or gas/liquid mixture) refrigerant goes back to the suction of the refrigerant compressor (1) after the gas/liquid separator (9) (to avoid possible liquid-shock). The high pressure protection switch (12) is applied to avoid refrigerant pressure over-limit. At no-load or quite low-load, the hot gas bypass valve (HGB) (13) would bypass the hot-gas-refrigerant from the compressor outlet to avoid possible freezing (iceblock) failure.

Automatic regulation system

The condenser pressure must be kept as constant as possible to obtain stable operation. The fan control switch therefore stops and starts the cooling fan (3). If, under partial or no load, the evaporator pressure drops below a certain level, the hot gas bypass valve (9) opens and hot, high-pressure gas is fed to the evaporator circuit to prevent the evaporator pressure from dropping any further.