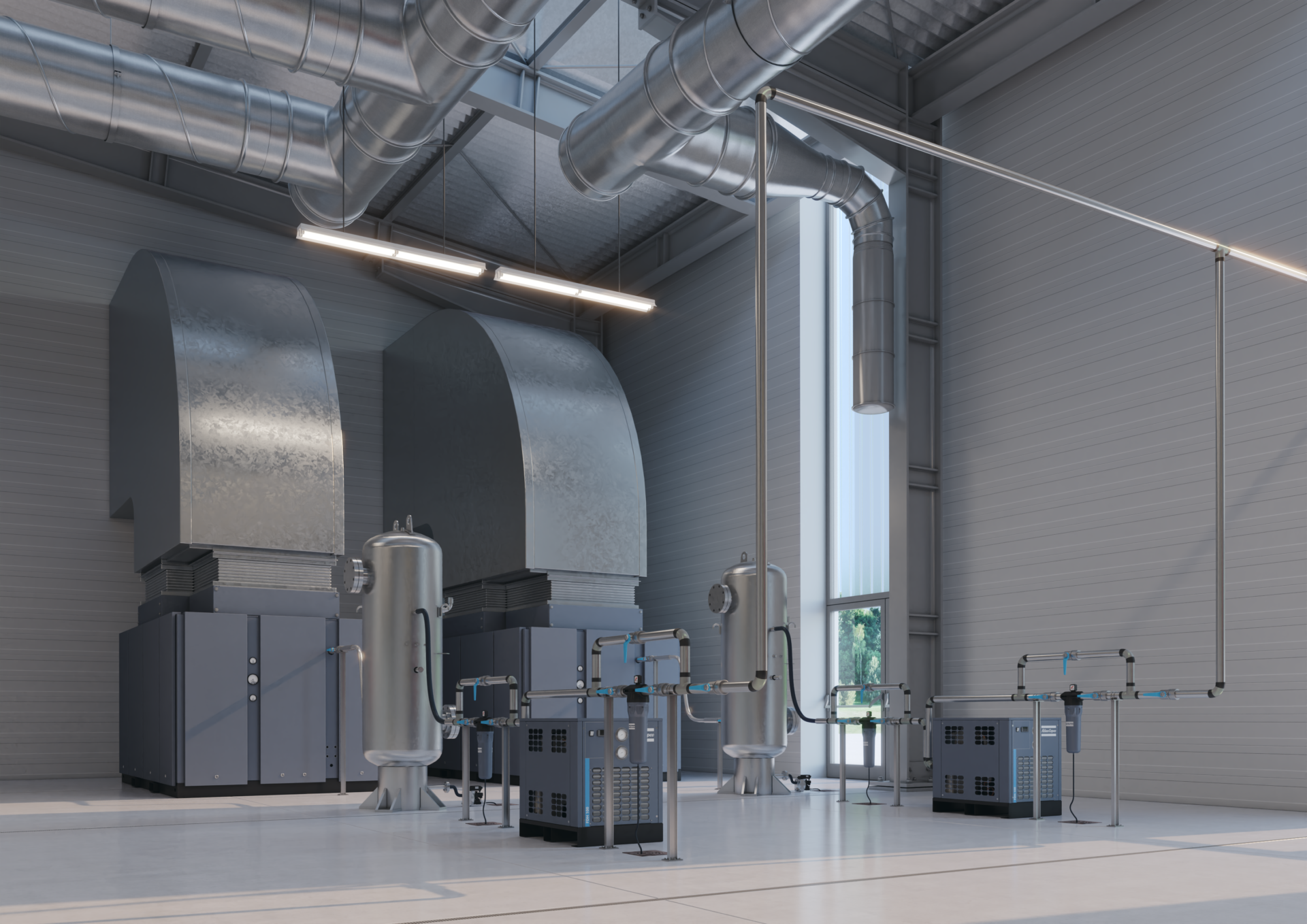

Designed to perform in heavy and even subtropical conditions, the HF dryer delivers you simple and reliable operation, excellent protection of your products and systems against damage or corrosion.

Air treatment

FDH 100

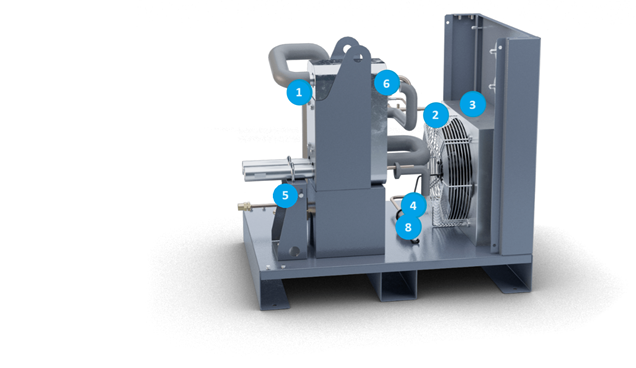

-

1

Heat exchanger

-

2

Motor fan

-

3

Condenser

-

4

Refrigerant filter

-

5

Electrical timer drain

-

6

Hot gas bypass valve

-

7

Refrigerant compressor

-

8

Capillary

-

9

High & low pressure gauge

-

10

LAT indicator

-

1

Heat exchanger

Minimum pressure drop and maximum heat transfer efficiency design.

Removal of nearly 100% condensate by mechanical separator.

No consumables.

-

2

Motor fan

Silent heat exchanger motor fan

-

3

Condenser

Copper pipes & aluminum fins to condense the refrigerant.

With a large exchange surface for high thermal exchange.

-

4

Refrigerant filter

To remove moisture and particles from the refrigerant system.

Maximum working pressure: 45 bar.

-

5

Electrical timer drain

Each of the dryer heat exchangers is equipped with a separate zero air loss automatic drain.

No additional connections or interconnections required that could cause leakages or drain system malfunctions.

-

6

Hot gas bypass valve

Regulates the amount of refrigerant passing through the air-to-refrigerant heat exchanger, ensuring a stable pressure dewpoint, and eliminating the chance of the condensate freezing.

-

7

Refrigerant compressor

Accurately sized for best performance with the lowest energy consumption in mind.

-

8

Capillary

Copper tube to reduce refrigerant pressure.

-

9

High & low pressure gauge

To indicate the evaporating & condensing pressure of the refrigerant.

-

10

LAT indicator

Lowest Air Temperature (LAT) measurement to verify the air quality.