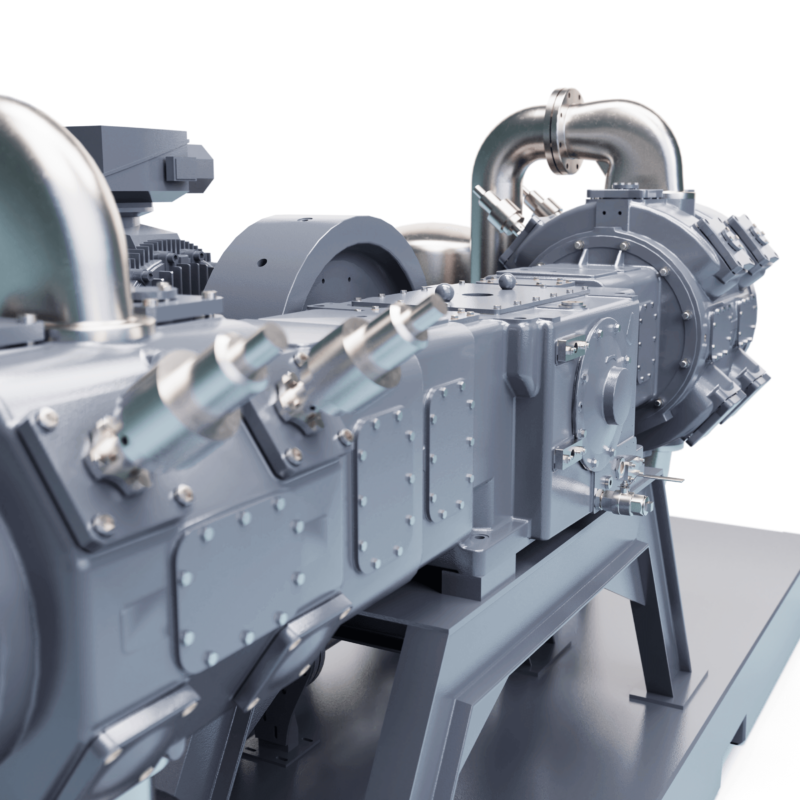

Engineered for hydrogen production

H2P compressors are designed specifically to meet the challenges of green hydrogen production. Along with maximum efficiency, we prioritized safe handling and reliable generation with the quality you need. Explore the highlights below to find out more.

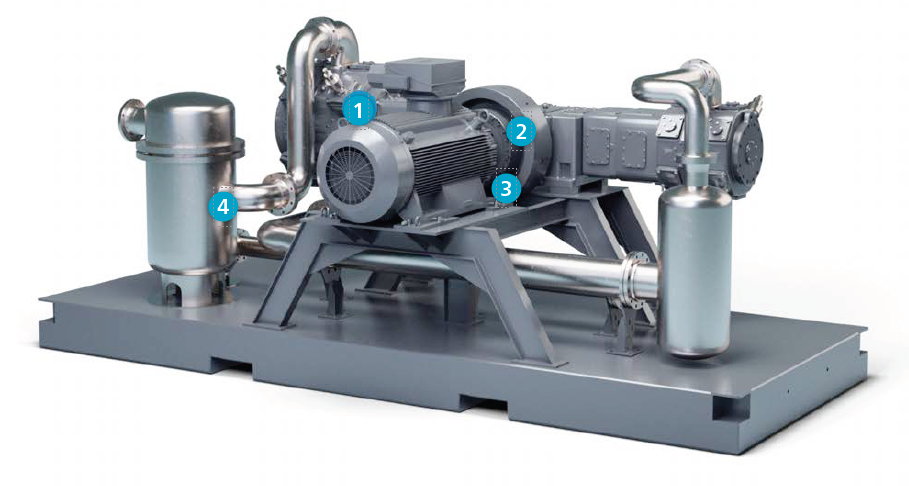

FRONT VIEW

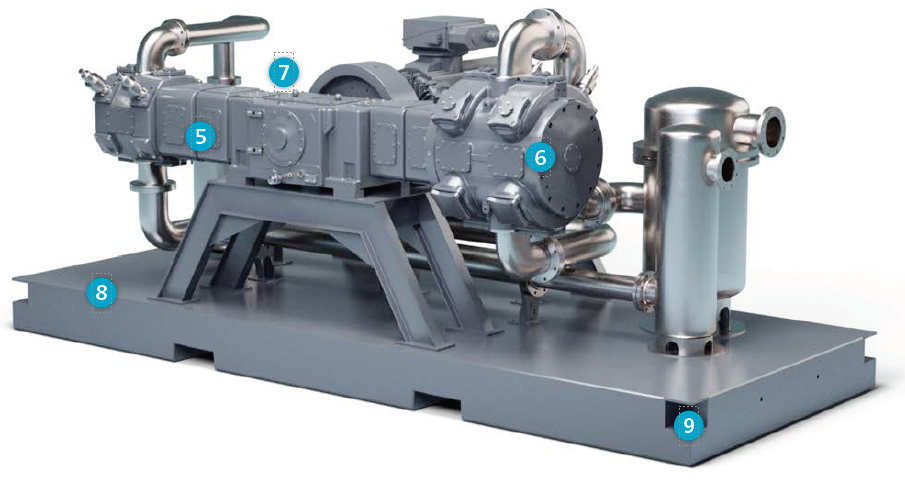

BACK VIEW

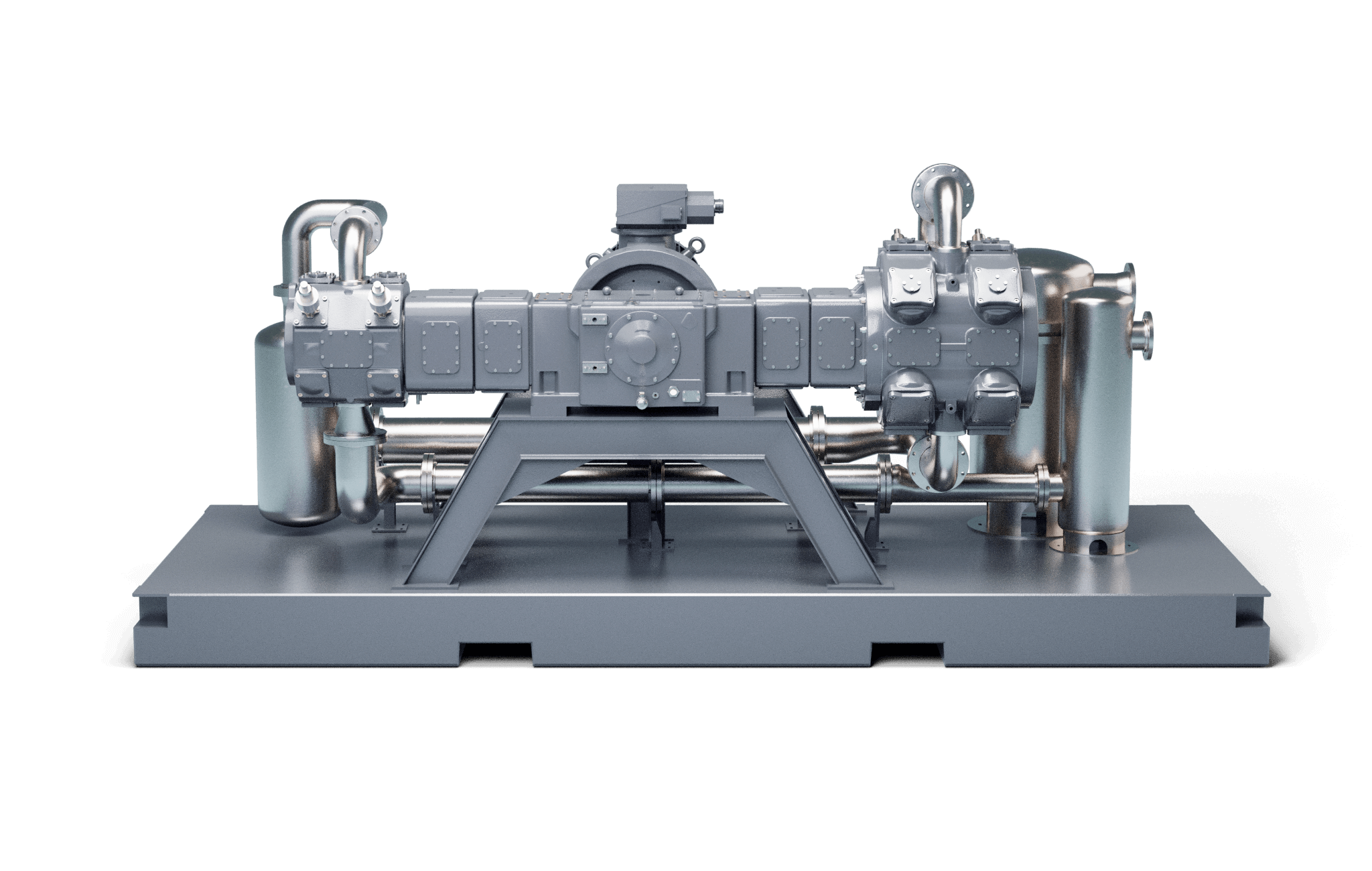

-

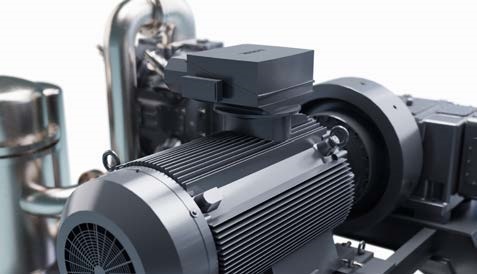

1

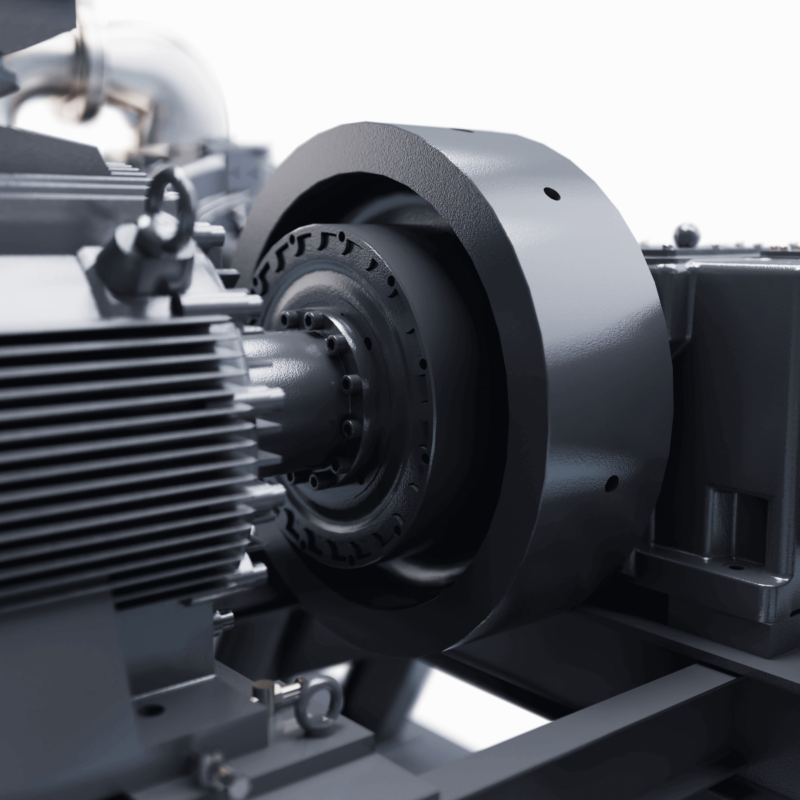

Premium VSD motor

-

2

Vibration-reducing flywheel

-

3

Power-saving drive train

-

4

Quality stainless steel components

-

5

Low maintenance costs

-

6

Long-life, oil-free piston technology

-

7

Advanced rod drop technology

-

8

Concrete base for easy installation

-

9

Integrated inlet gas train

-

1

Premium VSD motor

Follows hydrogen production easily

High energy efficiency

Prepared for classified areas

Soft coupling for long bearing lifetime

Safe electric motor with Variable Speed Drive

Our VSD technology can lead to further energy savings and improved regulation possibilities.

-

2

Vibration-reducing flywheel

Soft coupling and large inertia flywheel protected inside a cage to smooth the torque of the motor.

-

3

Power-saving drive train

Direct drive coupling to avoid transmission losses

Drive system designed for high energy efficiency

-

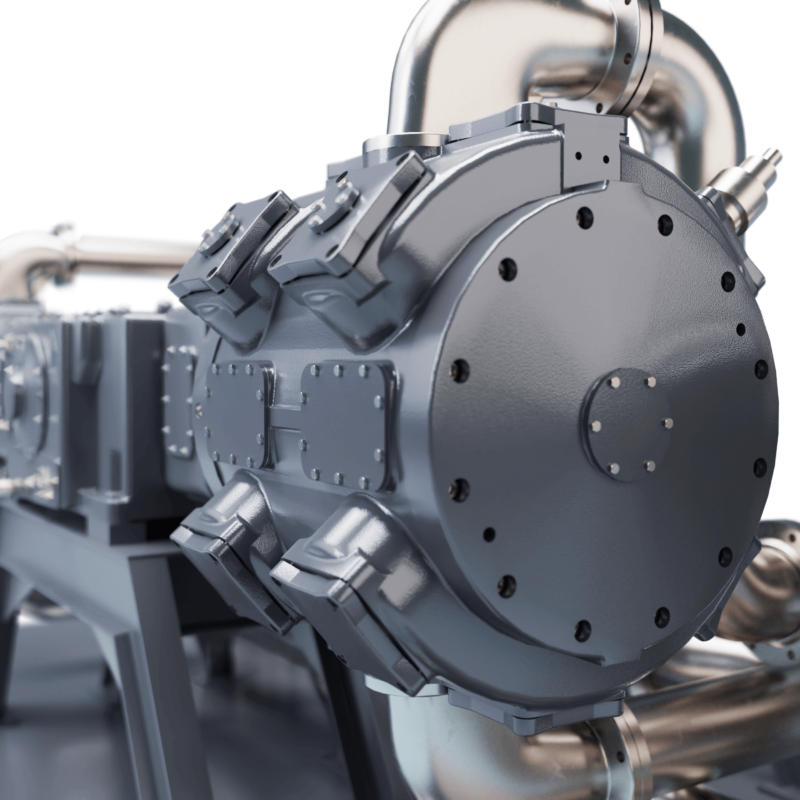

4

Quality stainless steel components

High-quality gas piping in stainless steel

Best in industry

Prepared to handle hydrogen

High reliability (25-year lifetime)

Zero contamination

Flexible connections for cooler and cylinder to reduce stress on mechanical components

-

5

Low maintenance costs

Low piston speed to minimize wear & tear

Long component lifetime

-

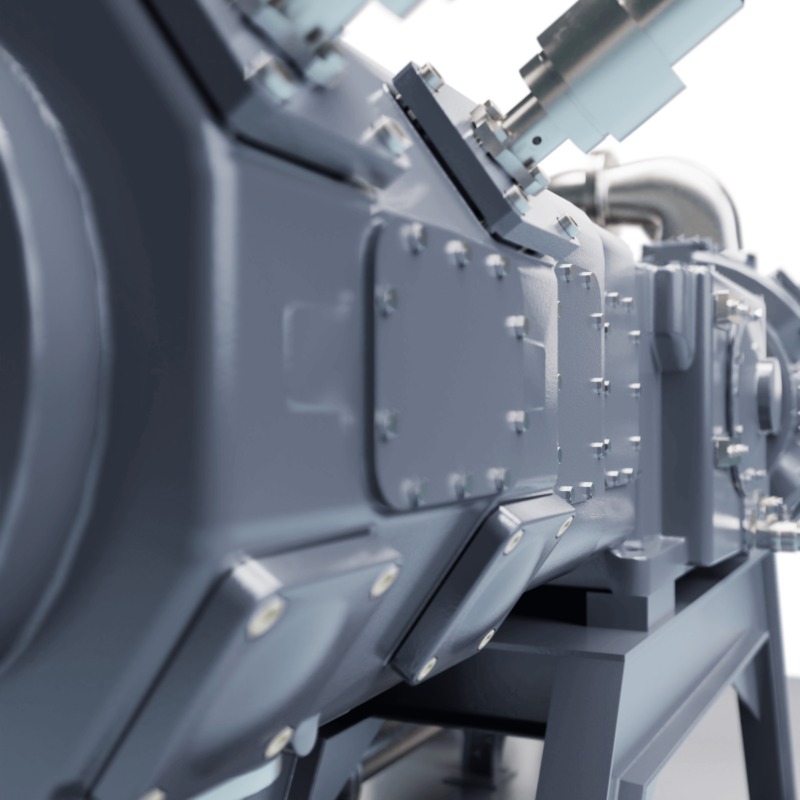

6

Long-life, oil-free piston technology

Balanced opposed piston rods arrangement to reduce noise and vibrations

PTFE piston rings for long life

Double distance pieces ensure compression chambers are perfectly oil-free

No risk of hydrogen contamination, damaged products, or losses from operational downtime

-

7

Advanced rod drop technology

We are the only manufacturer to integrate sensors to optimize availability and lower maintenance costs.

Horizontal design based on API618 (balances forces)

Reduced vibrations for longer component life

Designed for reliability

-

8

Concrete base for easy installation

Skid-mounted, Plug & Play

Compact footprint for containerization and transportation

High-duty compressor chair in fabricated steel

Slots for forklift handling

Vibration-absorbing frame

-

9

Integrated inlet gas train

Counter-current shell and tube heat exchangers in stainless steel (AISI 316L / X2CrNiMo17-12-2) after each compression stage to reduce the discharge temperature and the specific energy requirement.